Stainless Steel Air Borne Dust Suppression System

450000 INR/Set

Product Details:

- Instruments Type Fixed

- Display Type Digital

- Usage & Applications Industrial Dust Control, Mining, Cement Plants, Material Handling Units

- Air Flow 1000-30000 m/hr

- Automation Grade Automatic

- Efficiency Up to 99%

- Scrubber Type Wet Scrubber

- Click to View more

X

Stainless Steel Air Borne Dust Suppression System Price And Quantity

- 1 Set

- 450000 INR/Set

- 2-5 bar

- Flanged

- Ready to Use

- Yes

- HEPA/Pre-Filter Combination

- Stationary

- Low Maintenance Required

- Silver

- Fine Mist Atomizing

- 50-200 LPH

- Floor Mounted

- Programmable Logic Controller (PLC)

Stainless Steel Air Borne Dust Suppression System Product Specifications

- Automatic

- 3-5 mm

- Up to 99%

- Wet Scrubber

- 1000-30000 m/hr

- Digital

- 1000-30000 CFM

- Industrial Dust Control, Mining, Cement Plants, Material Handling Units

- Fixed

- Electric

- Air Borne Dust Suppression System

- 1800 x 900 x 1800 mm (approx.)

- Airborne Dust Level

- Less than 70 dB

- Polished Stainless Steel

- Continuous Operation

- 220-240 V AC

- Vertical

- Stainless Steel

- 350-500 kg

- Optical Sensor

- -10C to 60C

- Air Cooled

- 2-5 bar

- Flanged

- Ready to Use

- Yes

- HEPA/Pre-Filter Combination

- Stationary

- Low Maintenance Required

- Silver

- Fine Mist Atomizing

- 50-200 LPH

- Floor Mounted

- Programmable Logic Controller (PLC)

Stainless Steel Air Borne Dust Suppression System Trade Information

- 1 Set Per Day

- 4 Week

Product Description

All of us are aware of the grave problem created by DUST'.Though the word DUST' seems very simple but it creates different types of hazards for living & non livings beings. The Dust not only reduces the life of costly Plant & Machineries but also pollutes the climate, damaging Flora.

Dust fatally effects, God's most precious creation, the HUMAN' developing various types of diseases, causing reduction of life span of human being. The major Dust creation sources are Mining, Power Generation and other Industrial activities.

Though late, but the Government pollution Dept. and the Industry itself have taken a serious note of this fatal menace and are taking remedial action by installing Dust Suppression System.

In Mining sector apart from Dust Suppression System, the Government is also emphasizing on forestation on Over Burden sites.

We at Oasis' offer a tailored made system of Dust Suppression , various types of Rain Gun sprinklers for the Dry Fog System to suit a particular site or the Industry. Since long we have been serving the Indian Industries and the Mining Sector to combat the Dust menace.

For Over Burden sites of the Mining sector OASIS' Drip Irrigation System has brought a revolution toward the aforestation.

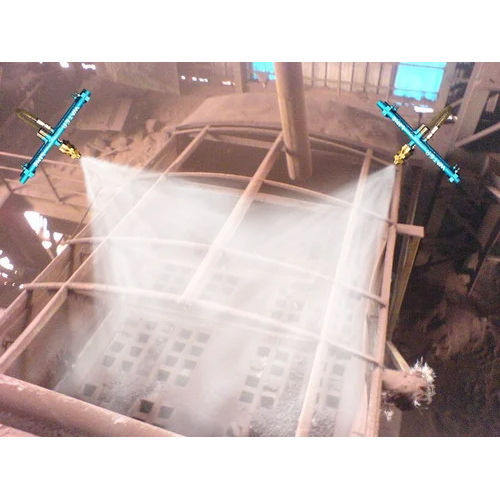

Precision Dust Suppression for Industrial Use

This system deploys fine mist atomizing spray coupled with advanced filtration (HEPA/Pre-filter), capturing airborne dust efficiently in demanding applications. Its stainless steel, air-cooled construction offers impressive durability and corrosion resistance, making it suitable for harsh environments such as mines, cement factories, and bulk material handlers.

Smart Automation and Continuous Efficiency

Equipped with a Programmable Logic Controller (PLC), this unit operates continuously and autonomously. Digital display and optical sensors monitor airborne dust levels, adjusting the spray and filtration in real-time to maintain optimal air quality around the clock.

Ready-to-Use Design with Minimal Maintenance

The system features a straightforward, ready-to-install configuration with flanged connections. Its low-maintenance design, polished surface, and air-cooled mechanism contribute to its long service life and operational reliability, minimizing downtime for industrial operations.

FAQ's of Stainless Steel Air Borne Dust Suppression System:

Q: How does the Stainless Steel Air Borne Dust Suppression System remove airborne dust?

A: The system uses fine mist atomizing spray nozzles combined with a HEPA/Pre-filter configuration to capture and settle airborne dust particles efficiently, reducing particulate levels in the environment by up to 99%.Q: What are the primary industrial applications for this dust suppression system?

A: This system is ideally suited for environments with high dust generation such as mining facilities, cement plants, and material handling units, where maintaining air quality is crucial for both safety and regulatory compliance.Q: Where should the system be installed, and what are the installation requirements?

A: Designed for floor-mounted, stationary placement, the unit is ready to use upon delivery. It requires a flat, stable surface and connection to a 220-240 V AC power source and water supply (50-200 LPH). Flanged connections enable straightforward integration into existing industrial setups.Q: What is the benefit of the programmable logic controller (PLC) in the control system?

A: The PLC allows automated and precise control of system operations, including dust measurement and response, spray timing, and filtration monitoring. This ensures efficient performance with minimal manual intervention.Q: How often does the system require maintenance?

A: Thanks to its robust stainless steel build and self-cleaning features, the system demands very low maintenance. Routine checks on spray nozzles and filters are typically sufficient for optimal continuous operation.Q: What is the process for measuring and controlling dust levels?

A: The system employs digital displays and optical sensors to continuously monitor airborne dust concentrations. Data is processed by the PLC, which adjusts spray and filtration rates to maintain targeted air purity levels.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Air Pollution Control Equipment' category

"We are accepting bulk order quantity."

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free